APPLICATION EXAMPLES

The Multi-Viscoelastic contact model

1. Introduction

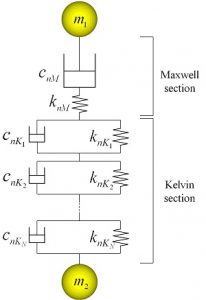

This new contact model was developed allowing to present viscoelasticity, which is embedded into the Discrete Element Method (DEM). The developed contact model, as shown in Figure 1, links to one Maxwell element and several Kelvin elements in series. Because this contact model allows to show the characteristics at each connecting points between the elements, it lets present localization, also mechanical characteristics as time depending viscoelasticity in bulk assembly.

Figure 1 Multi-Viscoelastic contact model: normal direction).

2. Stress relaxation and creep characteristics

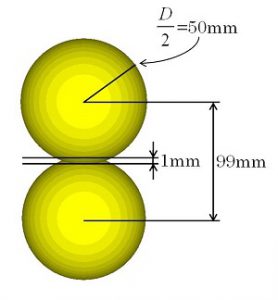

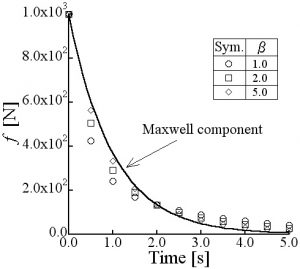

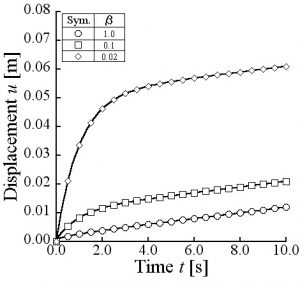

To examine this contact model, a simple numerical model (Figure 2) was created, followed by stress relaxation and creep simulation. The simulation of stress relaxation demonstrates transient of the contact force between two particles intruded reciprocally (mutually) on keeping its position. The result is shown in Figure 3. In the figure, the β corresponds to the ratio between the Maxwell element and the Kelvin element, and the greater β is (the value of the Maxwell element dominating), the result gets closer to analysis solution of the Maxwell element. Furthermore, in the creep simulation, displacements of the two particles (in case of normal direction, the quantity of insertion) were controlled to maintain the initial force, and it’s position (displacements) were measured. The result is shown in the Figure 4 (the solid lines in the figure marks the analytical solution,) and the calculated result matched well with the analytical solution.

Figure 2 Numerical model by two elements (particles)).

Figure3 Result from stress relaxation simulation: normal direction).

Figure4 Result from creep simulation: normal direction1).

3. Simulation of creep test on margarines

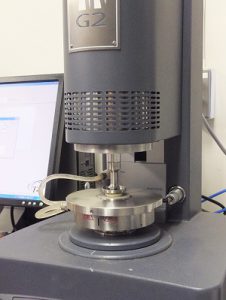

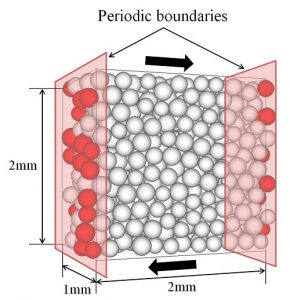

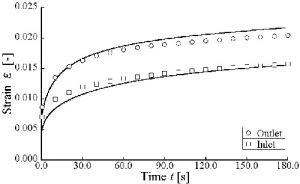

A numerical model, Figure 6 was created based on a creep test on margarines, Figure 5 to compare with the test results. As shown in Figure 7, the Multi-Viscoelastic contact model expresses well the creep characteristics on margarines.

Figure 5 Creep test device used on margarines).

Figure 6 Numerical model of creep test on margarines).

Figure 7 Result, mark: calculation, solid lines: test).

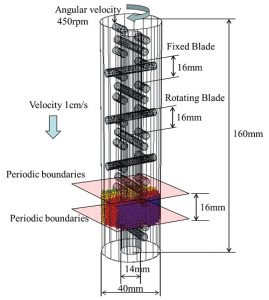

4. Application on manufacturing machines

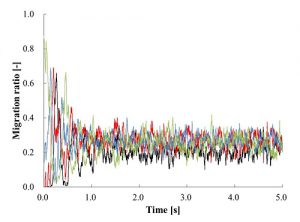

A simulation was conducted to demonstrate dynamics of margarines inside a mixing unit used for improvements on uniformity and filling ability of crystalline structure during the manufacturing processes of margarines. Figure 8 shows its numerical model. After composing the mixing unit with a cylindrical walls, spherical particles to be embedded with the Multi-Viscoelastic contact model is set in the space having width of 16mm, between the outer cylinder corresponding to casing and inner cylinder to axis of rotating axis. Then, periodic boundary conditions are put into place between both sides, making it seem filled up with particles inside the entire mixing unit. In this state, by rotating the rotating axis and the mixing pins connected to the rotating axis with a constant angular velocity, and moving the entire walls to the direction of the rotating axis with a constant velocity, the particles are carried to the direction of the rotating axis relative to the entire walls. The results are presented in the Figure 9. Moreover, transient of migration ratio from the initial state are shown in Figure 10. As simulation results, the migration ratio inside the mixing units was shown to differ depending on its characteristics of viscoelasticity, as well as the operations, enable one to give information on improvements in producing process and in quality of manufacturing machines.

Figure 8 Numerical simulation model on margarines inside the mixing unit.

Figure 9 General view of results of margarines inside the mixing unit.

Figure 10 Transient of migration ratio: movements of particles initially placed.

References

1) Shimizu, Y. et al., Multi-viscoelastic contact model in Discrete Element Method – Application to margarine’s process engineering-, Nihon Reoroji Gakkaishi, Vol. 40, No.5, pp257-266, (2012).

List

- Acceleration in calculation of Discrete Element Method

- The Multi-Viscoelastic contact model

- Lattice Boltzmann Method and coupling with Discrete Element Method

- Fixed coarse-grid thermal-fluid coupling scheme

- Particle-fluid coupling scheme considering the pore water pressure.

- 一次元ドリフトフラックスモデルを用いたレアアース泥揚鉱システムの性能計算

- 間隙水圧を考慮した粒子-流体連成スキームの適用事例